Recent content by deering

-

D

Axle time.

Only one way to find out. Lots of pressure of the axle pushing on the cross shaft then turning. The Teflon may wear good but may get distorted from the pressure. -

D

Axle time.

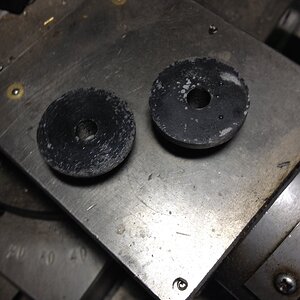

Hears the doover. Red drilled to 1/2 Machining new inserts out of annealed old trans shaft Forge warming up for hardening Yep they are hot, quenched in quench oil. After quench. Hears after repolishing and one annealed, the yellow one was put back in the forge and brought up to 400ish... -

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3

-

D

Axle time.

I wonder how the Teflon holds out? These should last the rest of the life of the car. I got in on the Monday sales so I have a bunch of stuff on the way. Mostly all the rubber parts for the suspension and Brgs and seals for the diff. -

D

Axle time.

I grew up tearing stuff apart. Now I have the tools to fix and put back together. I have enough to stuff to almost build anything except one thing lacking is time. I'll hopefully get some picks of the heat treating, anealing, and finished axle. I'm 1/2 hr from Red Deer you have a C3? -

D

Axle time.

Working on correcting axle end play. Drill small hole in the end of axle for a hardened stub to be pressed in. Hole is around .300, wear face is 1". Can't grab the big end in the lathe so both were attached using the u-joint. I annealed a junk automatic trans main shaft, will machine... -

image.jpeg

- deering

- Media item

- Comments: 0

- Category: Corvette C3